At 2:32 a.m. on November 16, the Shenzhou-19 crew received space deliveries. These deliveries were loaded on the Tianzhou-8 cargo craft which blasted off from the Wenchang Spacecraft Launch Site and took 3 hours and 17 minutes to make the delivery. Notably, the “lunar soil brick”, created by Prof. Ding Lieyun and his team from the School of Civil and Hydraulic Engineering of HUST to simulate the composition of lunar soil, was being taken aboard. The aim of the experiment was to confirm whether the “brick” can be used to construct houses on the moon. The first “brick” was scheduled to return to Earth by the end of 2025 after the space experiment.

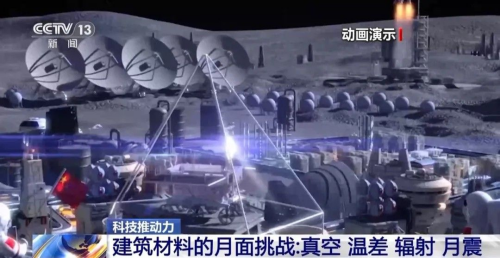

Why do the “bricks” need to be taken to the China’s space station? What kind of tests do they have to withstand before they can shoulder the task of constructing houses on the moon? Reports show that the first challenge maybe the drastic temperature changes. The daytime temperature on the moon can exceed 180 °C, yet it plunges to -190 °C during the night. Besides, in the absence of atmosphere, they will be bombarded by cosmic rays and micrometeorites. Meanwhile, there are moonquakes with high frequencies as well. All these factors will test the strength and durability of the building materials on the lunar surface. The HUST team will take advantage of this space journey to understand the degradation of the material under different forming processes and in the environment of the space station, so as to provide a scientific basis for material selection and process optimization.

According to Prof. Zhou Cheng from the National Center of Technology Innovator for Digital Constructor (NCTI-DC), the bricks were designed to be subjected to three years of exposure tests in space. “Therefore, every other year, we will downlink a sample plate, with samples that have been exposed in the space station, and then conduct relevant experiments.”

Are the “lunar-soil bricks” made of real soil on the moon? In May 2023, the HUST team was granted the lunar samples returned by the Chang'e-5 mission. The “bricks” were made of lunar soil simulant. The team analyzed the components of the real lunar soil, simulated the composition, and then sintered them. According to the introduction, the “lunar-soil bricks” have the same density as ordinary bricks, but their compressive strength is more than three times that of ordinary red bricks and concrete bricks, which means that they can bear a weight of over 1 ton on an area of 1 square centimeter.

To make full use of the precious opportunity to test the “bricks” in space, the team designed columnar bricks and sheet-like bricks. The columnar bricks are designed for mechanical tests, while the sheet-like bricks, with larger exposed areas, are created for thermal and radiation effect tests. The particle compositions of the soil vary in different sites and regions on the moon. Hence, apart from different shapes, these “lunar soil bricks” adopt 5 different lunar soil simulants and 3 kinds of forming processes.

As early as April 20, 2017, the verification of key technology from the CGE of HUST was loaded in the Tianzhou-1 cargo craft, which reached the Tiangong-2 space station after a two-day flight.

Images courtesy of CCTV news

Written by: Gu Yuxiao

Edited by: Yang Kunjie, Chang Wen, Peng Yumeng